Snapmaker U1: A Deep Dive into its Groundbreaking Hot-Swapping, Four-Head 3D Printing System

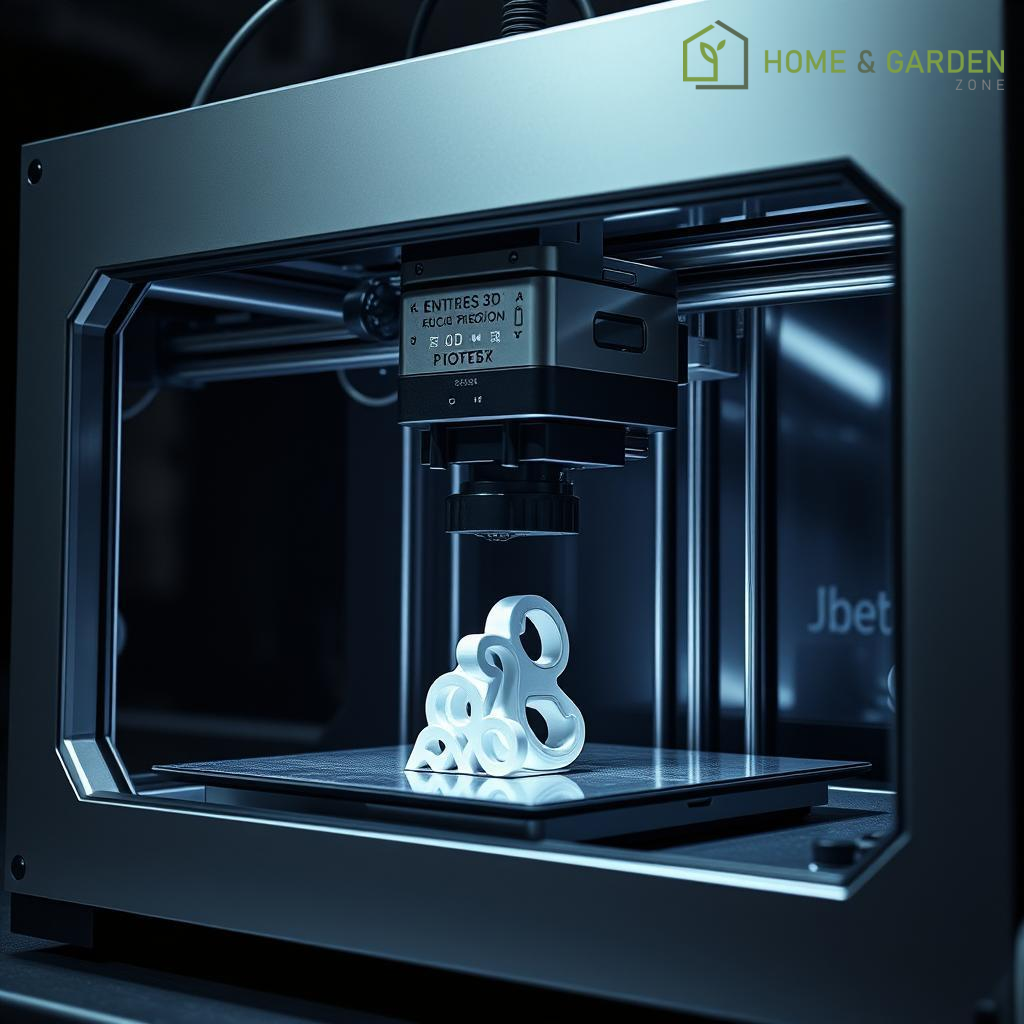

The additive manufacturing landscape is perpetually evolving, pushing the boundaries of what home and professional makers can achieve. Snapmaker, a name synonymous with versatility and modularity in the maker space, has once again captured attention with its latest offering: the Snapmaker U1. This new machine arrives with significant anticipation, promising to redefine efficiency in 3D printing through its innovative hot-swapping system and, most notably, four dedicated filament-saving tool heads.

The Modular Marvel: Hot-Swapping Redefined

At the core of the Snapmaker U1's appeal is its refined hot-swapping mechanism. Building on the brand's established reputation for seamless tool head interchangeability, the U1 elevates the experience. Users can transition between different functionalities in mere moments, a critical advantage for iterative design processes and diverse project requirements. This rapid adaptability not only streamlines workflow but also encourages experimentation, making the U1 a truly dynamic platform for creative endeavors.

Filament Efficiency at its Core: The Quad-Head Printing System

The marquee feature of the Snapmaker U1 is undoubtedly its specialized suite of four filament-saving tool heads, each engineered to optimize material usage and enhance print quality across various applications. This focused approach addresses a pervasive concern among 3D printing enthusiasts: material waste.

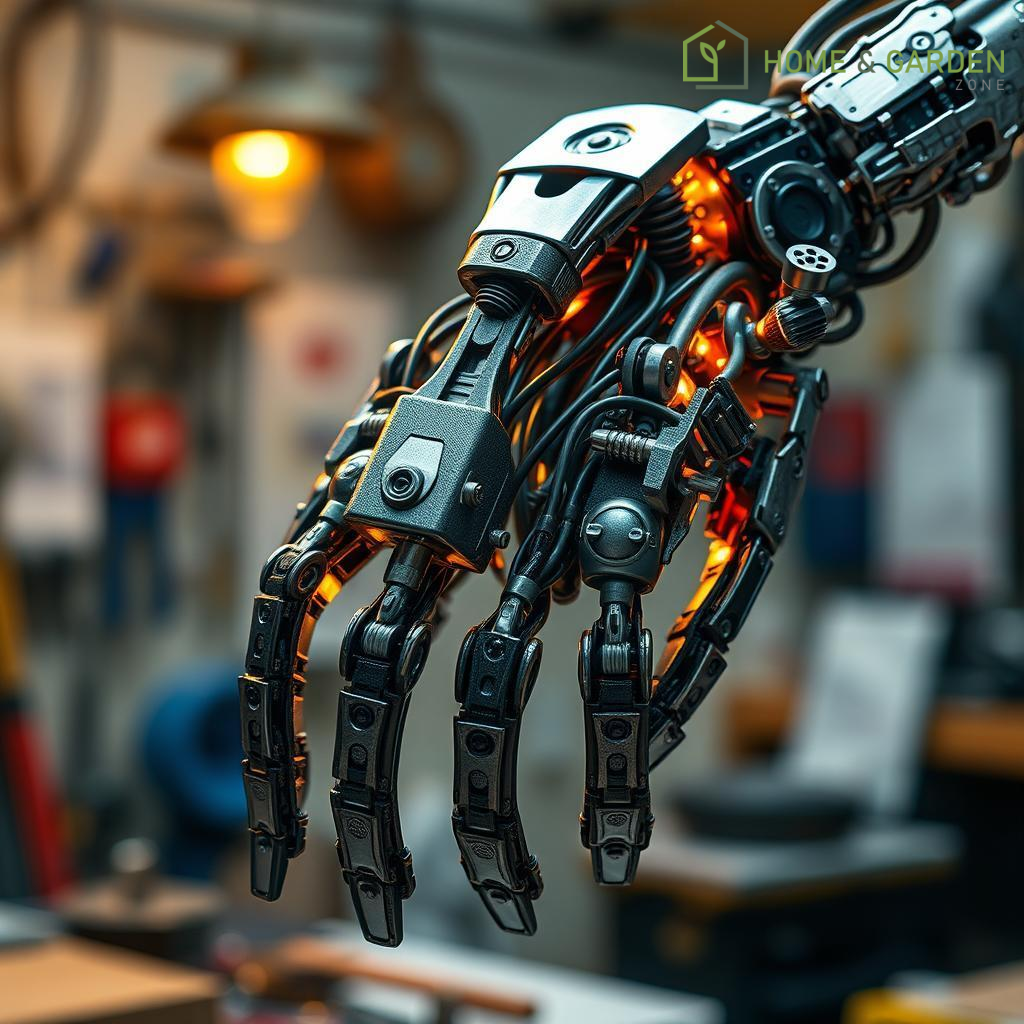

Precision FDM Head

This primary 3D printing head features an advanced extrusion system meticulously designed to minimize stringing and oozing. Its optimized nozzle geometry and refined thermal control ensure precise material deposition, drastically reducing common printing flaws that lead to wasted filament and failed prints. Ideal for intricate models and high-detail work, it ensures every millimeter of filament counts.

Dual-Extrusion IDEX Head

For complex geometries requiring support structures or multi-material designs, the U1 introduces a sophisticated Independent Dual Extruder (IDEX) head. This configuration enables printing with soluble support materials or multiple colors/materials with significantly reduced purge blocks compared to traditional dual-extrusion systems. By precisely controlling each nozzle independently, the IDEX head minimizes material waste during transitions and offers unparalleled efficiency in multi-material applications.

High-Speed & Large Volume FDM Head

Addressing the need for rapid prototyping and larger prints, this specialized head combines high-flow extrusion with intelligent software algorithms. It leverages adaptive infill patterns and optimized travel paths to achieve faster print times while consuming less material than conventional large-format printers. The result is a substantial reduction in both time and filament required for substantial objects, without compromising structural integrity.

Specialized Material Optimization Head

The fourth tool head is a testament to Snapmaker’s commitment to sustainable and innovative materials. Engineered to precisely handle challenging filaments—from recycled plastics to advanced composites—it incorporates unique extrusion profiles and enhanced temperature control. This specialization ensures higher success rates when working with finicky materials, effectively preventing print failures and, consequently, saving valuable and often costly specialized filaments. It also features integrated diagnostics that provide real-time feedback on material flow and print integrity.

A Forward Leap for the Modern Maker

The Snapmaker U1 positions itself not merely as a new 3D printer, but as a comprehensive ecosystem for efficient additive manufacturing. Its emphasis on hot-swapping capability combined with dedicated filament-saving technologies signals a thoughtful evolution in how makers interact with their tools. By reducing material waste and streamlining workflow, the U1 empowers users to undertake more ambitious projects with greater confidence and a reduced environmental footprint.

Summary

The Snapmaker U1 is poised to make a significant impact on the desktop manufacturing scene. Its modularity, epitomized by the hot-swapping feature, and the introduction of four distinct, filament-saving 3D printing tool heads represent a strategic advancement. This machine addresses critical concerns around material efficiency and versatility, offering a compelling solution for both hobbyists and professionals seeking an intelligent, adaptable, and economical additive manufacturing platform.

Resources

Details

Author

Top articles

You can now watch HBO Max for $10

Latest articles

You can now watch HBO Max for $10

The additive manufacturing landscape is perpetually evolving, pushing the boundaries of what home and professional makers can achieve. Snapmaker, a name synonymous with versatility and modularity in the maker space, has once again captured attention with its latest offering: the Snapmaker U1. This new machine arrives with significant anticipation, promising to redefine efficiency in 3D printing through its innovative hot-swapping system and, most notably, four dedicated filament-saving tool heads.

The Modular Marvel: Hot-Swapping Redefined

At the core of the Snapmaker U1's appeal is its refined hot-swapping mechanism. Building on the brand's established reputation for seamless tool head interchangeability, the U1 elevates the experience. Users can transition between different functionalities in mere moments, a critical advantage for iterative design processes and diverse project requirements. This rapid adaptability not only streamlines workflow but also encourages experimentation, making the U1 a truly dynamic platform for creative endeavors.

Filament Efficiency at its Core: The Quad-Head Printing System

The marquee feature of the Snapmaker U1 is undoubtedly its specialized suite of four filament-saving tool heads, each engineered to optimize material usage and enhance print quality across various applications. This focused approach addresses a pervasive concern among 3D printing enthusiasts: material waste.

Precision FDM Head

This primary 3D printing head features an advanced extrusion system meticulously designed to minimize stringing and oozing. Its optimized nozzle geometry and refined thermal control ensure precise material deposition, drastically reducing common printing flaws that lead to wasted filament and failed prints. Ideal for intricate models and high-detail work, it ensures every millimeter of filament counts.

Dual-Extrusion IDEX Head

For complex geometries requiring support structures or multi-material designs, the U1 introduces a sophisticated Independent Dual Extruder (IDEX) head. This configuration enables printing with soluble support materials or multiple colors/materials with significantly reduced purge blocks compared to traditional dual-extrusion systems. By precisely controlling each nozzle independently, the IDEX head minimizes material waste during transitions and offers unparalleled efficiency in multi-material applications.

High-Speed & Large Volume FDM Head

Addressing the need for rapid prototyping and larger prints, this specialized head combines high-flow extrusion with intelligent software algorithms. It leverages adaptive infill patterns and optimized travel paths to achieve faster print times while consuming less material than conventional large-format printers. The result is a substantial reduction in both time and filament required for substantial objects, without compromising structural integrity.

Specialized Material Optimization Head

The fourth tool head is a testament to Snapmaker’s commitment to sustainable and innovative materials. Engineered to precisely handle challenging filaments—from recycled plastics to advanced composites—it incorporates unique extrusion profiles and enhanced temperature control. This specialization ensures higher success rates when working with finicky materials, effectively preventing print failures and, consequently, saving valuable and often costly specialized filaments. It also features integrated diagnostics that provide real-time feedback on material flow and print integrity.

A Forward Leap for the Modern Maker

The Snapmaker U1 positions itself not merely as a new 3D printer, but as a comprehensive ecosystem for efficient additive manufacturing. Its emphasis on hot-swapping capability combined with dedicated filament-saving technologies signals a thoughtful evolution in how makers interact with their tools. By reducing material waste and streamlining workflow, the U1 empowers users to undertake more ambitious projects with greater confidence and a reduced environmental footprint.

Summary

The Snapmaker U1 is poised to make a significant impact on the desktop manufacturing scene. Its modularity, epitomized by the hot-swapping feature, and the introduction of four distinct, filament-saving 3D printing tool heads represent a strategic advancement. This machine addresses critical concerns around material efficiency and versatility, offering a compelling solution for both hobbyists and professionals seeking an intelligent, adaptable, and economical additive manufacturing platform.

Resources

Top articles

You can now watch HBO Max for $10

Latest articles

You can now watch HBO Max for $10

Similar posts

This is a page that only logged-in people can visit. Don't you feel special? Try clicking on a button below to do some things you can't do when you're logged out.

Example modal

At your leisure, please peruse this excerpt from a whale of a tale.

Chapter 1: Loomings.

Call me Ishmael. Some years ago—never mind how long precisely—having little or no money in my purse, and nothing particular to interest me on shore, I thought I would sail about a little and see the watery part of the world. It is a way I have of driving off the spleen and regulating the circulation. Whenever I find myself growing grim about the mouth; whenever it is a damp, drizzly November in my soul; whenever I find myself involuntarily pausing before coffin warehouses, and bringing up the rear of every funeral I meet; and especially whenever my hypos get such an upper hand of me, that it requires a strong moral principle to prevent me from deliberately stepping into the street, and methodically knocking people's hats off—then, I account it high time to get to sea as soon as I can. This is my substitute for pistol and ball. With a philosophical flourish Cato throws himself upon his sword; I quietly take to the ship. There is nothing surprising in this. If they but knew it, almost all men in their degree, some time or other, cherish very nearly the same feelings towards the ocean with me.

Comment